In the realm of papermaking, the selection of appropriate sizing agents is of paramount importance to achieve desired paper properties. Among the various options available, Poly Aluminium Chloride (PAC) has emerged as a significant and widely utilized compound. This article aims to delve deep into the role and significance of PAC as a paper sizing agent, exploring its characteristics, benefits, and potential applications.

The use of Poly Aluminium Chloride PAC white powder in paper sizing offers several distinct advantages. Firstly, it exhibits excellent sizing efficiency, ensuring that the paper has enhanced resistance to water penetration and absorption. This is crucial for a wide range of paper products, from packaging materials to fine writing papers, as it helps maintain the integrity and quality of the paper when in contact with liquids.

Moreover, Poly Aluminium Chloride PAC white powder provides superior bonding capabilities, enhancing the strength and durability of the paper. This is especially important in applications where the paper is subjected to mechanical stress or handling. The strong bonds formed by PAC contribute to the overall stability and reliability of the paper product.

In addition to its functional benefits, Poly Aluminium Chloride PAC white powder also offers certain processing advantages. It is relatively easy to handle and incorporate into the papermaking process, and its stability in various conditions ensures consistent performance. The controlled dosage of PAC can be adjusted to meet specific sizing requirements, allowing for fine-tuning of the paper properties.

When considering the use of Poly Aluminium Chloride PAC white powder as a sizing agent, it is essential to take into account several factors. The quality and composition of the raw materials used in papermaking can significantly impact the performance of PAC. Different types of fibers and additives may interact differently with PAC, requiring careful optimization of the process parameters.

Furthermore, environmental considerations also play a role. PAC is known for its relatively low environmental impact compared to some other sizing agents. However, proper handling and disposal procedures must still be adhered to in order to minimize any potential negative effects on the environment.

To illustrate the effectiveness of PAC, let us consider a case study of a paper mill that switched from a traditional sizing agent to PAC. The results showed a significant improvement in the sizing performance, with reduced water absorption and enhanced paper strength. This led to increased customer satisfaction and improved the competitiveness of the mill in the market.

In conclusion, Poly Aluminium Chloride PAC white powder has firmly established itself as a valuable and reliable paper sizing agent. Its combination of excellent sizing efficiency, bonding capabilities, and processing advantages make it an attractive option for papermakers worldwide. By carefully considering the factors mentioned above and continuously optimizing the process, the full potential of PAC in paper sizing can be unlocked, leading to high-quality and sustainable paper products. The future looks bright for the continued use and development of PAC in the papermaking industry, as it continues to play a vital role in meeting the ever-growing demands for high-performance paper.

How to choose Poly Aluminium Chloride PAC type used as paper sizing agent?

Compared with Poly Aluminium Chloride PAC other types,Poly Aluminium Chloride PAC white powder is high-purity poly aluminum chloride. It consists of a series of different degrees of polymerization of inorganic polymer compounds .The main composition is Al13O4 (OH) 24 (H2O) 127+ highly charged poly-aluminum ions chain. Paper sizing agent PAC white powder is made of pure aluminum hydroxide and high-pure hydrochloric acid, after high temperature and high pressure step, we delete FE content to get high-purity polyaluminum chloride products. In this way, the basicity can be controlled(among 40-60),the color is white or milk white, without affecting the color of white paper.

Despite aluminium sulphate is is widely used for paper sizing, however, in recent years as neutral sizing technology developed, aluminium sulphate showed negative effects obviously, such as equipment corrosion, paper strength declined, anti-aging performance poor and limitation usage of calcium carbonate.

Compared with the aluminum sulfate, poly aluminum chloride used as paper sizing agent has the following characteristics:

1) a large number of multi-core with a positive charge, shape stability of hydroxy aluminum complexes, can effectively promote flocculation, sizing.

2) white color, low content of iron, can meet the needs of manufacturing high quality paper.

3) poly-aluminum chloride hydrolysis is relatively low, pulp pH value gap decline smaller than the aluminum sulfate.

4) aluminum sulfate is only suitable for acid sizing and polymeric aluminum chloride can glue in acidic and neutral environment, corrosion of the system decreased significantly, white water treatment easier.

5) calcium carbonate can be used. not only reduces production cost and improve the whiteness of the paper and folding, while overcoming the synthetic plastic material (such as AKD) inevitable shortcomings (such as skidding, sizing is difficult to control, and so on).

6) pulp retention and drainage AIDS in greatly increased.

7) paper performance addition to the breaking length, other indicators improved.

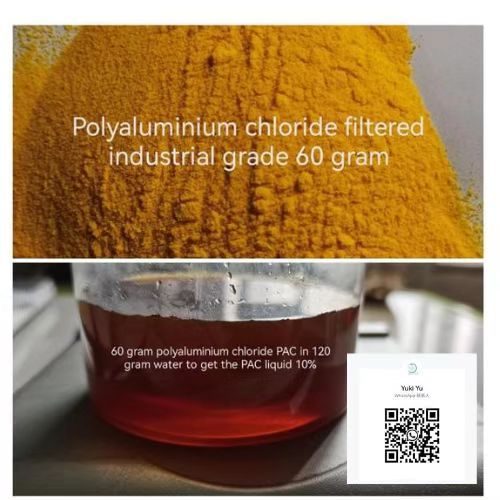

Usage:

Make solid powder to 10% solution ,then add 1.5-3% liquid to pulp and mix. Compared with aluminium sulphate , the dosage is only one third of it. For dry paper, the dosage is 2-3%.